South Australian Medical Heritage Society Inc

Website for the Virtual Museum

Home

Coming meetings

Past meetings

About the Society

Main Galleries

Medicine

Surgery

Anaesthesia

X-rays

Hospitals,other organisations

Individuals of note

Small Galleries

Ethnic medicine

- Aboriginal

- Chinese

- Mediterran

Centrifuges in Medicine and Nuclear Physics

The use of centrifuges dates to the early 13th century when they were used to separate cream from milk.

They were operated manually and the speeds of rotation were in the low thousands. Later, electric motors were added.

The medical uses include the separation of blood cells from blood (plasma), and the removal of fibrinogen (serum).

They were also used to determine the haematocrit and to separate urinary components. Several of these were still hand driven.

Centrifuges have several uses in the home, including spin dryers, removing excess water from salads, various blenders, and cyclonic vacuum cleaners.

The following photographs show a centrifuge manufactured by the Heka company, and donated to the SAMHS society Dr. Couper-Smartt.

The rotation causes a force perpendicular to the axis of rotation. The centrifugal force acts upon the sample

media causing objects of different density to accelerate at different rates. This leads to the separation and banding

of different density materials, with the least dense nearest the centre of rotation.

As the centrifugal force is proportional to the radius of rotation and the square of the angular velocity,

centrifugation protocols usually specify acceleration (in multiples of gravity, or "g"s) rather than RPM.

This acceleration is traditionally called "relative centrifugal force", or "RCF".

where:

r is the radius of rotation (m)

ω is the angular velocity (radians/s)

g is the standard acceleration due to gravity (m/s2)

This can be rewritten as:

RCF = 1.11824396 x 10-5 r N2

where:

r is radius in centimeters (cm)

N is RPM

Specifying the RCF allows machines with different radii to produce the same amount of force, and hence, produce the same results.

|

|

|

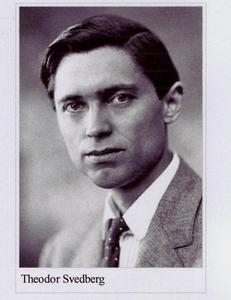

Theodor Svedberg (left) received the Nobel prize in Chemistry in 1926 for research on colloids and proteins

using the high speed ultracentrifuge (close to 900,000 g) he developed in 1925.

With the ultracentrifuge he was able to determine the molecular weight and subunit structure of many complex

proteins, haemoglobin in particular.

The units of the sedimentation co-efficient are named Svedberg (S) in his honour. Because ribosomes and their subunits

were first isolated by ultracentrifugal sedimentation, they were named from their sedimentation co-efficients.

For example, the two eukaryotic ribosomal subunits are referred to as the 40S and 60S subunits.

Further improvements were made by an American physicist called Jessie Beams. He developed a shaftless rotor,

suspended by a magnetic field in a strong vacuum. This allowed for far higher rotation rates, and greatly reduced

frictional heating.

Edward Pickles, a student of Beams, continued to refine this design. In 1946 he co-founded Spinco (Specialized

Instruments Corp), the first company to commercially manufacture ultracentrifuges.

Spinco was bought by Beckman Instruments (now called Beckman Coulter) in 1955.

The Beckman machines (such as the one above-right) were used in many research laboratories world wide.

The high speeds of ultracentrifuges require special alloys and very low tolerance machining to prevent mechanical failure.

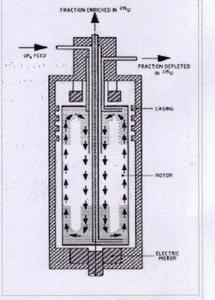

A more controversial use of the centrifuges is in the nuclear industry. It involves the separation of uranium 235

from the much more common U-238. A small difference of only 3 neutrons, but a major step in the production of

fissile material.

The process used is called gas centrifuging. In this instance, a gas called uranium hexa-fluoride is used.

High speed rotation by magnetic motors and heating of the gas moves the heavier U-238 to the periphery and the lower

weight isotope can be collected from the centre of the tube.

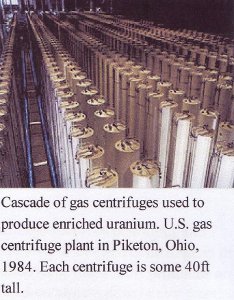

Because of the difficulty, production rates are low,

requiring many centrifuges to supply enough material for a nuclear reactor.

Depending on the percentage of the U-235 needed, (for a reactor it is about 3.5%, and greater than 90% for

a nuclear bomb) this may need to be repeated many times.

|

|

|

-o0o-